Hoʻokumu a Crimping Mekini Hoʻohui

ʻO ka wehewehe pōkole:

Hōʻike huahana

ʻO ka mīkini hoʻoheheʻe kila ma mua

ʻO kaʻO ka mīkini hoʻoheheʻe kila ma muaua maheleia i elua mahele:Paipu huinahaHolomuaMekini Hoohuoi Paipu KinoaWelded Steel Pipe Roll Forming Machine.

E like me ka cross-sectional shape hiki ke maheleia iPaha Tube Roll Forming Machinea me Roll Forming Machine, i hoʻohana nui ʻia mapaipu kila poepoe, akā, aia kekahi mau semi-circular, hexagonal, equilateral triangle, octagonal shape steel pipe.

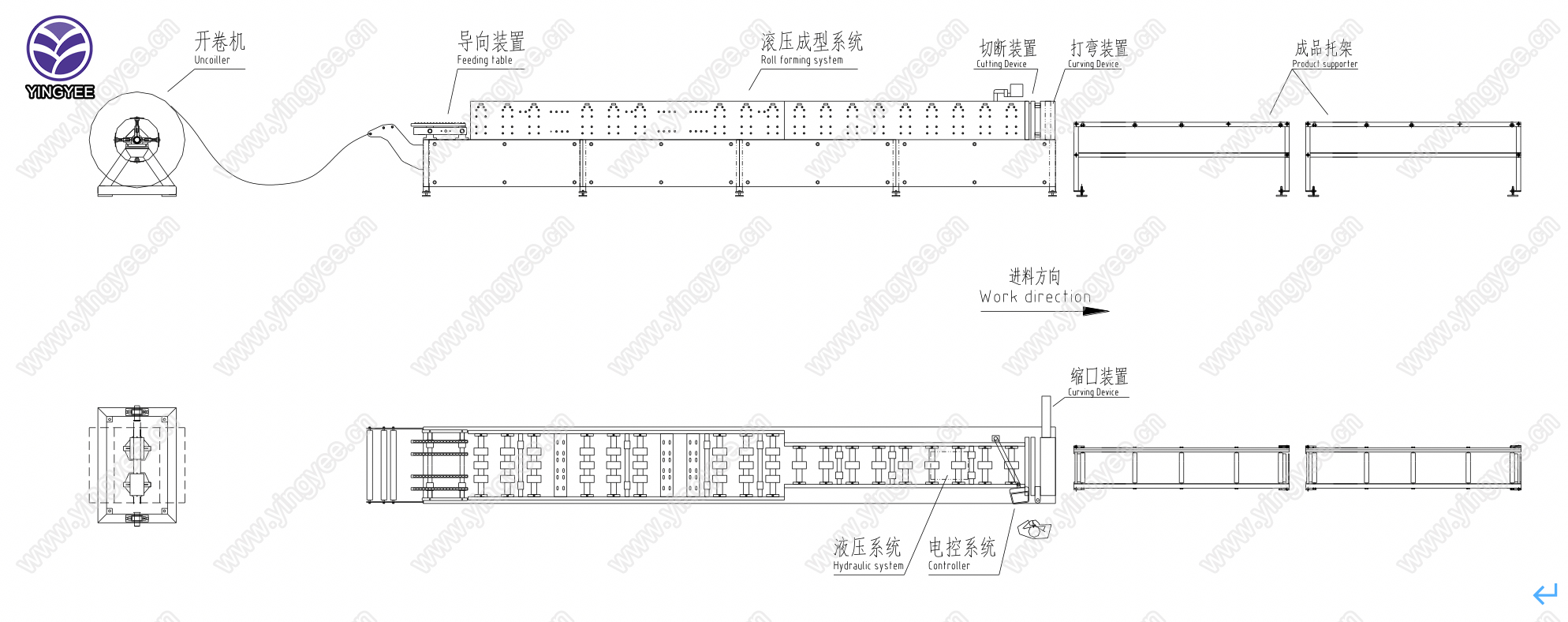

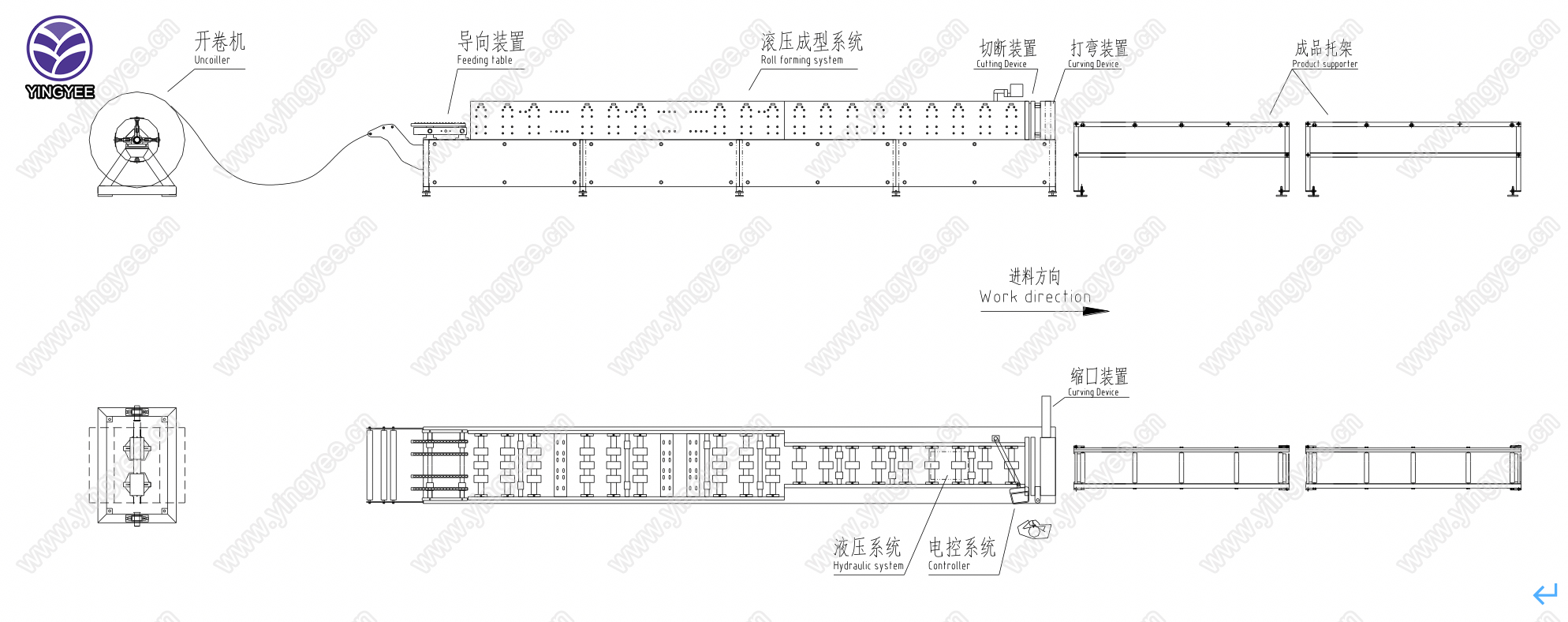

Ke Kaʻina Hana:Decoiler - Ke alakaʻi hānai - Mīkini Hoʻohui Nui - PLC Contol System - Hydraulic Cutting and crimping - Output Table

Nā palena ʻenehana:

| Mea maka | PPGI a i ʻole GI |

| Laulā mānoanoa mea | 0.2-0.8mm |

| Nā Rollers | 18 lālani |

| Mea o ka hana wili | 45 # kila me chromed |

| ʻO ke anawaena kumu a me ka mateiral | 76mm, he 40Cr ka mea |

| Mea ʻoki ʻoki | Cr12 mold kila me ke kinai ʻia |

| Hoʻokumu wikiwiki | 12-18m/min (koe ʻole ka ʻoki ʻana i ka manawa hoʻomaha) |

| Mana kaʻa nui | 5.5 KW |

| Ka mana hoʻokele hydraulic | 3KW |

| ʻO ke ʻano o ka ʻoki ʻana | ʻOki Hydraulic a ʻoki ʻike lele a ʻoki ʻoki ʻia paha |

| Pūnaehana hoʻomalu | PLC Frequency Control System me ka pale lima |

.jpg)

E hoʻouna i kāu leka iā mākou:

E kākau i kāu leka ma aneʻi a hoʻouna mai iā mākou

-225x300.jpg)